About Australian Metrology & Calibration

At AMC our mindset is based on continuous improvement and investment in technology. Since 2013 the company has acquired additional specialised equipment capable of automated measurements using software specifically designed to produce accurate, reliable inspection reports.

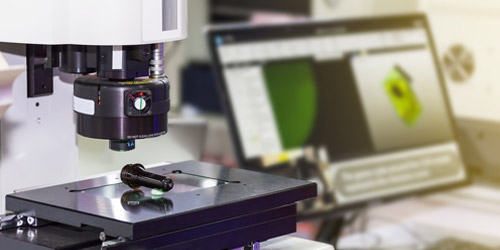

The latest investment is the Starrett Vision System providing automated measuring with optional touch sensor and rotary indexer. Designed for small to very large components our Starrett LED CNC Vision System has a 711 x 610 x 300mm travel with an Accuracy of (2.5 + 5L/1000) µm. The system is a multi-purpose CNC measurement system which incorporates LED illumination, video edge detection with a high resolution digital colour video camera. . The Starrett Vision System is capable of accurate non-contact visual measurements of components, including plastic and aluminium.

AMC have the capability to calibrate all types of measuring equipment and manufactured components to meet the quality and compliance requirements of Australian Industries.

Provides superb accuracy and repeatable measurement results for a wide range of precision measurement applications.

|

Starrett Vision System Provides superb accuracy and repeatable measurement results for a wide range of precision measurement applications. |

I-Checker Specially designed to calibrate dial and digital test indicators. |

|

Wyler Inclinometer for measuring straightness, flatness, squareness and machine geometry. |

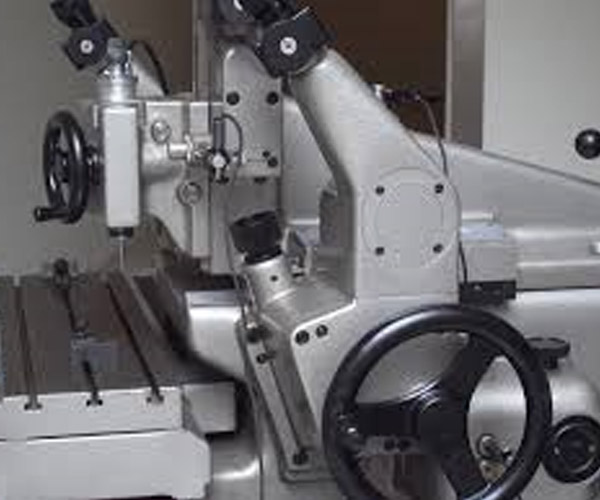

Sip Used to calibrate and measure micrometers, steel tapes, precision linear scales and manufactured components. |